Copper busbar is widely used in electrical field, such as transformer, switch contact, switchgear, distribution cabinet, generator unit and etc.

| Model No. | Name | Chemical Composition (%) | Tensile Strength (Mpa) | Elongation (%) | 20 ℃ DC Resistivity (Ω•mm^2/m) | Conductivity (%IACS) |

| TMR | Copper Busbar (S) | Cu ≥ 99.95% | ≥ 206 | ≥ 35 | ≤ 0.017241 | ≥ 100 |

| TMY | Copper Busbar (H) | Cu ≥ 99.95% | ≤ 0.01777 | ≥ 97 |

Product specifications:

Thickness: 2mm~65mm;

Width: 15mm~300mm (soft, hard, half-hard)

Thickness: 70mm~80mm; Width: 15mm~80mm(soft)

Standards:

1. GBT 5585.1-2005

2. ASTM B187-2015

3. JIS H3140-2012

Capacity:

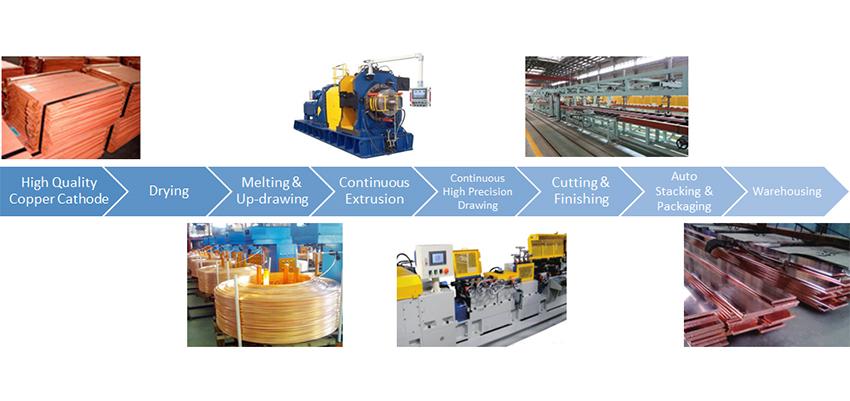

Three continuous extrusion line has been built in the first phase of this project, achieved 20,000 MT annual capacity of high precision and high conductivity copper busbar.

Delivery Time:

1. Delivery time for regular size products is in 3~7 days.

2. For special size products open new mold is necessary. Time for open new mold is in 5~10 days.

Customization:

For anti-corrosion purpose, tin coating or silver coating is available.